-

Bruno NascimentoDziękuję za waszą pomoc i wsparcie w dostarczaniu wysokiej jakości i przystępnych cen produktów.

Bruno NascimentoDziękuję za waszą pomoc i wsparcie w dostarczaniu wysokiej jakości i przystępnych cen produktów. -

Ehsan SalmariSzybka odpowiedź i profesjonalna postawa sprawiają, że nasza współpraca jest płynniejsza!

Ehsan SalmariSzybka odpowiedź i profesjonalna postawa sprawiają, że nasza współpraca jest płynniejsza!

System Sterowania Turbiny GE Mark V DS215GASQG4AZZ01A 200mm x 100mm

Skontaktuj się ze mną, aby otrzymać bezpłatne próbki i kupony.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype'a: sales10@aixton.com

W razie jakichkolwiek wątpliwości zapewniamy całodobową pomoc online.

x| Nazwa | GE DS215GASQG4AZZ01A System sterowania | Identyfikator produktu | DS215GASQG4AZZ01A |

|---|---|---|---|

| Szereg | Mark v | Wysokość netto produktu | 200 mm |

| Szerokość sieci produktu | 100 mm | Głębokość/długość netto produktu | 330 mm |

| Gwarancja | 1 rok | Waga netto produktu | 2 kg |

| Podkreślić | System sterowania turbiną GE Mark V,Sterownik turbiny DS215GASQG4AZZ01A,Moduł sterowania GE 200mm x 100mm |

||

GE DS215GASQG4AZZ01A System sterowania turbiną Mark V serii

Opis produktu:

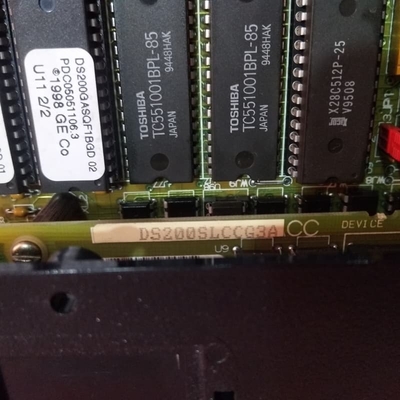

GE Mark VDS215GASQG4AZZ01Ajest zintegrowaną kartą sterowania napędem, która łączy w sobie podstawowe funkcjeDS200SDCCG4AEC(główny moduł sterowania napędem) iDS200SLCCG3ACC(płytka pomocnicza komunikacji LAN), dostosowana do systemu sterowania turbiną GE Mark V. Jako spójna jednostka centralizuje sterowanie napędem, przetwarzanie sygnałów i możliwości komunikacji LAN,zapewnienie bezproblemowego działania gazu, napędów turbin parowych lub wiatrowych przy wykorzystaniu legatycznej technologii sterowania Speedtronic Mark V.

W sprawieDS200SDCCG4AECPodstawowy moduł zawiera trzy wyspecjalizowane mikroprocesory:

Procesor sterowania napędem (DCP): zarządza dekodowaniem, bezpośrednim dostępem do pamięci (DMA) i wejściem/wyjściem (I/O) na poziomie systemu;

Procesor sterowania silnikiem (MCP): obsługuje funkcje sterowania silnikiem prądu stałego/przejściowego, takie jak sterowanie fazami;

Co-Motor Processor (CMP): Przetwarza zadania o dużym zaangażowaniu matematycznym wykraczające poza możliwości MCP.

Zawiera również współdzieloną pamięć RAM do jednoczesnego dostępu wieloprocesorowego,10 diod LED przedniego panelu do monitorowania funkcji w czasie rzeczywistym i wykrywania usterek (wyświetlające kody usterek w binarnym kodzie dziesiętnym/BCD lub binarnym w zależności od nasilenia usterki), a także konfigurowalny sprzęt (sprzęg JP typu Berg i sprzęg drutu WJ, głównie fabrycznie ustawione) do optymalizacji systemu.umożliwienie jednostce integracji z sieciami lokalnymi oraz rozszerzenie łączności i wymiany danych z innymi komponentami systemu.

Kluczowe cechy:

Zintegrowana konstrukcja podwójnych modułów:Łączy DS200SDCCG4AEC (rdzeń sterowania napędem) i DS200SLCCG3ACC (komunikacje LAN), eliminując konieczność instalacji oddzielnych modułów i uproszczając okablowanie systemu.

Wydajność potrójnego procesora:DCP, MCP i CMP pracują we współpracy), aby zapewnić dokładność i szybkość reakcji sterowania napędem, spełniając wysokie wymagania dynamicznego działania turbin.

Połączenie LAN:DS200SLCCG3ACC umożliwia bezproblemową integrację LAN, wspierając transmisję danych między kartą sterowania napędem a innymi urządzeniami sieciowymi do scentralizowanego monitorowania i sterowania.

Intuicyjna diagnostyka błędów:10 LED zapewniają wyraźne wizualne informacje zwrotne na temat stanu systemu; kody awarii (w BCD lub binarnej formie) umożliwiają szybką identyfikację problemów, skracając czas rozwiązywania problemów.

Konfiguracja i rozbudowa:Zaprojektowane fabrycznie sprzęty JP/WJ zapewniają kompatybilność, podczas gdy przyczepy DS200SDCCG4AEC obsługują dodatkowe karty opcjonalne (np. procesory sygnału) do przyszłej rozbudowy funkcji.

Bezpieczna instalacja i wymiana:Podczas konserwacji wymagane jest odłączenie zasilania; moduły EPROM z wadliwych urządzeń mogą być ponownie wykorzystywane na płytkach zamiennych,i prześcieracze nylonowe zapobiegają uszkodzeniu śrub, zapewniając bezpieczne i trwałe montaż.

![]()

![]()